Precision and Power Unleashed: The 400 Watts Die-Making Steel and Plywood Laser Cutting Machine

2023-10-18

Introduction

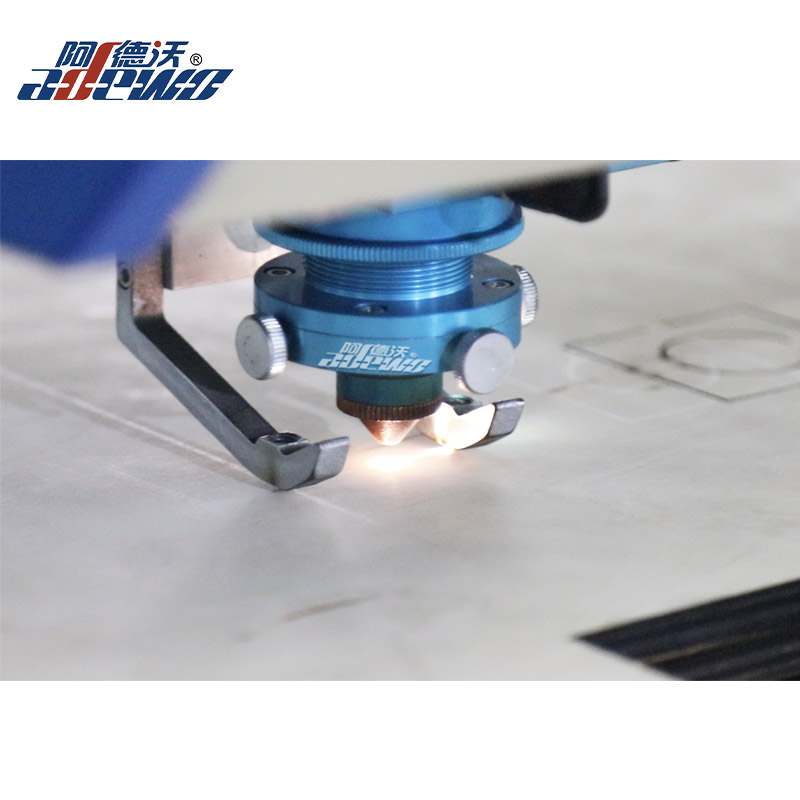

In the realms of manufacturing and design, precision and efficiency are paramount. The 400-watt die-making steel and Plywood Laser Cutting Machine is a technological marvel that combines power, precision, and versatility. This cutting-edge machine is revolutionizing the die-making industry, offering unparalleled capabilities in steel and plywood cutting. In this blog, we will explore the features, capabilities, and significance of the 400-watt die-making steel and Plywood Laser Cutting Machine.

Understanding the 400 Watts Die-Making Steel and Plywood Laser Cutting Machine

The 400-Watt Die-Making Steel and Plywood Laser Cutting Machine is a high-powered laser cutting system designed specifically for die-making applications. It utilizes a focused laser beam to precisely cut and engrave steel and plywood materials, making it an indispensable tool in industries such as packaging, printing, and die manufacturing.

Key Features of the 400-Watt Die-Making Steel and Plywood Laser Cutting Machine

1. High Laser Power: With a 400-watt laser source, this machine offers exceptional cutting power, allowing it to effortlessly cut through steel and plywood materials with precision.

2. Precision and Accuracy: The machine is equipped with advanced laser control technology that ensures precise and accurate cutting, even for intricate and complex designs.

3. Versatile Material Compatibility: It can cut and engrave a wide range of materials, including stainless steel, carbon steel, plywood, acrylic, and more, making it highly versatile for various applications.

4. User-Friendly Software: The machine is typically equipped with user-friendly software that allows for easy design import, customization, and cutting parameter adjustments.

5. Safety Features: Safety mechanisms such as laser beam guards, emergency stop buttons, and ventilation systems ensure operator safety during operation.

6. High-Speed Operation: The high-speed cutting and engraving capabilities of this machine significantly reduce production time, improving overall efficiency.

Applications of the 400-Watt Die-Making Steel and Plywood Laser Cutting Machine

The versatility and precision of the 400-watt die-making steel and Plywood Laser Cutting Machine make it a valuable asset in various industries and applications.

1. Die-Making: In the packaging and printing industries, this machine is used to create intricate and precise dies for cutting, embossing, and scoring operations.

2. Prototyping: It is employed in product design and prototyping to quickly create accurate models and prototypes from steel and plywood materials.

3. Signage and Engraving: The machine is used for creating custom signage, awards, plaques, and engraved products with intricate designs and fine details.

4. Metalworking: In metalworking and fabrication, it aids in the precise cutting, shaping, and engraving of steel components for various applications.

5. Woodworking: For woodworking projects that require detailed designs and precision cuts on plywood, this machine is an invaluable tool.

6. Art and Craft: Artists and craftsmen use this laser cutter to create intricate and detailed artwork on a variety of materials.

Conclusion

The 400-watt die-making steel and Plywood Laser Cutting Machine represents a significant advancement in precision cutting and engraving technology. Its high laser power, precision, versatility, and speed make it an indispensable tool in die-making, prototyping, metalworking, woodworking, and various other industries. As manufacturing and design demands continue to evolve, this cutting-edge machine will remain at the forefront, driving innovation and efficiency in diverse sectors.