The Colorful World of Inks and Coatings: The Essential Role of Petroleum Resin

2024-03-18

In the realm of printing and surface finishing, inks and coatings are the unsung heroes that bring vibrancy, protection, and functionality to a variety of products. Behind the scenes of these colorful creations lies a key ingredient: petroleum resin. In this blog, we'll explore the pivotal role that petroleum resin plays in the manufacturing of inks and coatings, enhancing color dispersion, durability, and performance across diverse applications.

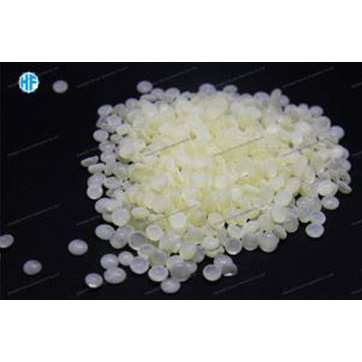

Understanding Petroleum Resin:

Petroleum resin is a synthetic resin derived from petroleum feedstocks through polymerization processes. It possesses unique properties, including solubility, viscosity, and adhesion, making it an indispensable component in ink and coating formulations.

Enhancing Color Dispersion:

1. Binder and Carrier:

Petroleum resin serves as a binder and carrier for pigments and dyes in ink formulations, ensuring uniform dispersion and stable coloration. Its solubility in various solvents allows for efficient dispersion of colorants, resulting in vibrant, consistent hues in printed materials.

2. Color Stability:

The compatibility of petroleum resin with pigments and dyes contributes to the color stability of inks, minimizing color shifting and fading over time. This ensures that printed materials retain their visual appeal and readability, even under prolonged exposure to light, heat, and environmental factors.

Improving Durability and Protection:

1. Film Formation:

In coatings formulations, petroleum resin facilitates film formation and adhesion to substrates, creating a protective barrier that enhances durability and resistance to abrasion, moisture, and chemical exposure. This ensures long-lasting protection for surfaces such as metal, wood, and plastics.

2. Weather Resistance:

Coatings formulated with petroleum resin exhibit excellent weather resistance, withstanding exposure to UV radiation, humidity, and temperature fluctuations. This makes them suitable for outdoor applications, such as architectural coatings, automotive finishes, and industrial coatings.

Enabling Formulation Flexibility:

1. Viscosity Control:

Control over viscosity is essential in ink and coating formulations to achieve proper flow, coverage, and film thickness. Petroleum resin offers versatility in viscosity adjustment, allowing formulators to tailor inks and coatings for specific printing methods, substrates, and application requirements.

2. Drying Characteristics:

Petroleum resin influences the drying characteristics of inks and coatings, affecting drying speed, film formation, and surface curing. By adjusting the type and amount of petroleum resin, formulators can achieve optimal drying times and cure properties, maximizing productivity and efficiency in printing and coating processes.

Diverse Applications:

1. Printing and Packaging:

Petroleum resin-based inks are widely used in various printing processes, including flexographic, gravure, and offset printing. They are employed in packaging, labels, publications, and promotional materials, offering vibrant colors, sharp graphics, and excellent print quality.

2. Surface Finishing:

Coatings formulated with petroleum resin are applied to surfaces for decorative, protective, or functional purposes. They are used in architectural coatings, automotive paints, industrial finishes, and specialty coatings for electronics, appliances, and consumer goods.

Conclusion:

Petroleum resin plays a vital role in the manufacturing of inks and coatings, enhancing color dispersion, durability, and performance across a wide range of applications. Whether in printing, packaging, or surface finishing, petroleum resin-based inks and coatings offer reliability, versatility, and aesthetic appeal, driving innovation and efficiency in the world of visual communication and surface protection. With its indispensable contributions, petroleum resin continues to shape the landscape of printing and coatings industries, enabling vibrant colors, durable finishes, and lasting impressions in our colorful world.