Reliable Flow Control with LYV Floating Ball Valves for Demanding Industrial Applications

2025-06-12

When it comes to reliable fluid control in high-pressure, high-temperature, and safety-critical environments, floating ball valves have proven to be one of the most effective solutions. Among the top-tier products in this category, LYV® floating ball valves stand out due to their precision engineering, robust construction, and compliance with international standards. Designed for durability and operational excellence, these valves offer dependable shutoff performance across a wide range of industries, including oil and gas, petrochemical, power generation, and more.

LYV® floating ball valves are manufactured through rigorous processes that emphasize quality at every stage. From raw material selection to final inspection, every valve undergoes meticulous quality control to ensure it not only meets but exceeds the requirements of global certifications. These valves conform to leading international standards such as API-6A, API-6D, ASME B16.34, and ISO 17292, demonstrating their credibility and readiness for complex industrial systems. Additionally, they are certified under API-6FA for fire safety, making them a trusted option for facilities that must adhere to strict fire protection regulations.

The design of LYV® floating ball valves integrates high-performance sealing technology to deliver leak-free operation under extreme service conditions. With sealing options that include PTFE, RPTFE, FPM, PEEK, and metallic combinations such as 304/316 with STL or Inconel overlays, these valves provide flexibility to match diverse operating media and temperatures. This variety ensures compatibility with aggressive fluids, steam, corrosive gases, and other challenging flow substances. Whether the application requires chemical resistance or extended lifecycle operation, the right seat material can be selected to meet exacting process demands.

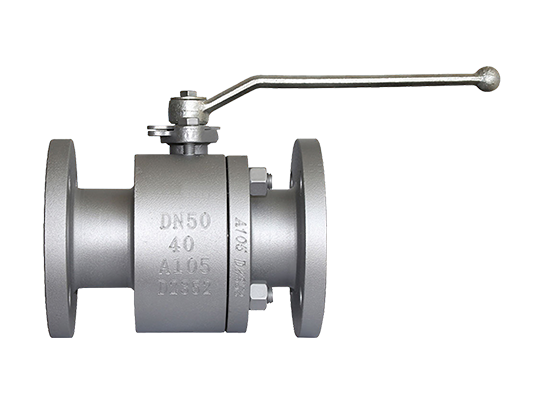

The construction materials of LYV® floating ball valves are selected to maximize corrosion resistance and mechanical strength. Standard body materials include ASTM A216 WCB/WCC, ASTM A352 LCB/LCC, ASTM A351 CF8M, and ASTM A105, while ball and stem components are crafted from ASTM A182 F304 or F316 stainless steel, ensuring durability and precise control under variable temperature and pressure conditions. These valves are suitable for applications with temperature ranges from -46℃ to 121℃, depending on the design and materials selected.

Offered in sizes from NPS 1/2” to 10” (DN15 to DN250) and with pressure ratings from 150LB to 1500LB (PN20 to PN260), LYV® floating ball valves accommodate a broad spectrum of system requirements. The standard end connections include flanged types, conforming to ASME B16.5 and B16.25, ensuring easy integration with existing piping systems. The face-to-face dimensions comply with ASME B16.10 and EN 558-1, ensuring interchangeability with other valve designs and supporting global installation needs.

At LYV®, we understand that industrial applications can vary widely, which is why we offer customized floating ball valve solutions to match specific technical and environmental needs. Our expert engineering and sales teams are ready to consult on projects of all sizes, offering tailored recommendations for materials, configurations, and performance specifications.

In conclusion, LYV® floating ball valves combine internationally certified design, premium materials, and adaptable sealing technologies to deliver unmatched performance in critical flow control applications. Their fire safety certification, pressure and temperature resistance, and versatile configurations make them a top choice for engineers and procurement teams who value safety, reliability, and operational efficiency. For more information or to discuss your unique application requirements, we invite you to contact our team directly.