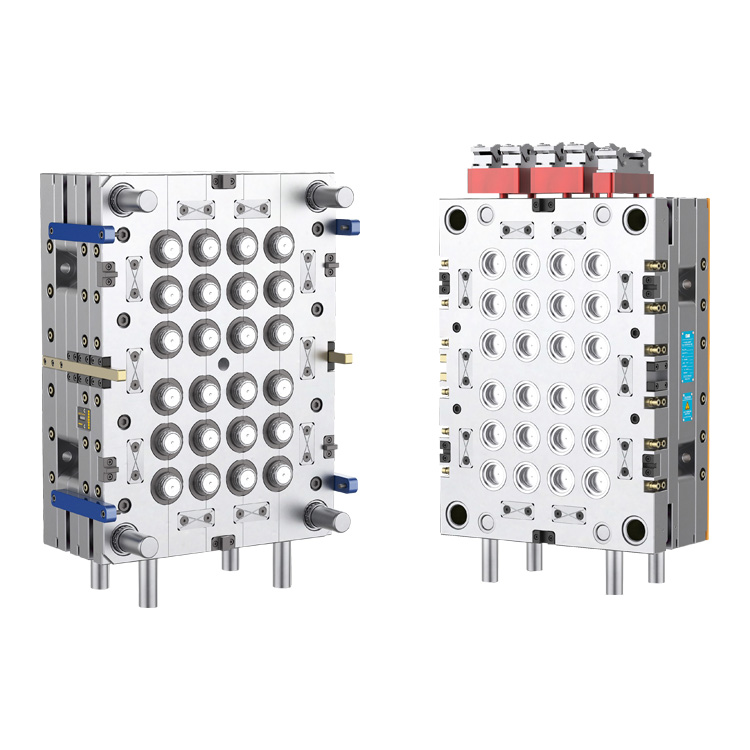

Precision Partners: Matching a 24-Cavity 38mm Cap Mold with the Right Injection Molding Machine

2024-01-17

Introduction:

The synergy between a 24-cavity 38mm cap mold and an injection molding machine is critical in achieving high-volume production with precision and efficiency. Selecting the right type of injection molding machine is pivotal for ensuring seamless operation and optimal performance. This blog explores the common types of injection molding machines paired with a 24-cavity cap mold, delving into the factors that influence this strategic partnership.

1. High-Speed Injection Molding Machines:

High-speed injection molding machines are a popular choice for pairing with a 24-cavity 38mm cap mold, especially when rapid cycle times are essential. These machines excel in delivering fast and precise injection movements, optimizing the production process for high-volume applications.

2. Hydraulic Injection Molding Machines:

Hydraulic injection molding machines offer robust power and force capabilities, making them suitable for applications like cap molding where high clamping forces are required. Their reliability and ability to handle heavy-duty molding tasks make them a viable choice for a 24-cavity cap mold.

3. Electric Injection Molding Machines:

Electric injection molding machines are known for their energy efficiency and precision. They are commonly paired with 24-cavity cap molds to achieve accurate control over injection movements and ensure consistent quality. The ability to fine-tune parameters contributes to the optimization of the molding process.

4. Toggle-Type Injection Molding Machines:

Toggle-type machines are characterized by their fast cycle times and high clamping force capabilities. This makes them suitable for use with 24-cavity cap molds, allowing for efficient and reliable production of caps in large quantities.

5. Servo-Driven Injection Molding Machines:

Servo-driven machines offer advanced control over the injection process, allowing for precise adjustments in speed, pressure, and position. The versatility of servo-driven technology is advantageous in meeting the demands of a 24-cavity mold for 38mm caps.

6. Two-Platen Injection Molding Machines:

Two-platen machines provide enhanced rigidity and stability, making them suitable for large molds like the 24-cavity cap mold. These machines offer ample space for accommodating multiple cavities and ensure uniform clamping force distribution.

7. Multi-Material Injection Molding Machines:

In cases where multi-material or multi-color capabilities are required, multi-material injection molding machines are chosen. This technology allows for the production of caps with intricate designs or special features, enhancing the versatility of the molding process.

8. Micro-Injection Molding Machines:

When precision and intricate details are paramount, micro-injection molding machines may be considered. These machines are designed for molding small and delicate components, offering precision in shot control for applications with fine details.

Conclusion:

Choosing the right type of injection molding machine is a crucial decision in optimizing the performance of a 24-cavity 38mm cap mold. The selection is influenced by factors such as cycle time requirements, precision specifications, energy efficiency, and the overall demands of high-volume production. As technology continues to evolve, the pairing of innovative injection molding machines with advanced molds remains central to achieving efficiency, precision, and reliability in cap production.