How is the abrasive material bonded to the bronze matrix in these wheels

2023-11-04

The abrasive material is bonded to the bronze matrix in grinding wheels through a process known as sintering. Sintering involves the application of heat and pressure to create a solid bond between the abrasive grains and the bronze matrix. Here's how the process works:

1. Preparation of Abrasive Material: The abrasive material, which can be aluminum oxide, silicon carbide, diamond, or other abrasive grains, is typically available in the form of granules or grains. These abrasive grains should be appropriately sized and graded to achieve the desired coarseness or fineness in the grinding wheel.

2. Mixing: The abrasive grains are mixed with a binder or adhesive material, such as a powdered form of the bronze matrix or a similar bonding agent. This mixture creates a homogenous blend of abrasive grains and binder.

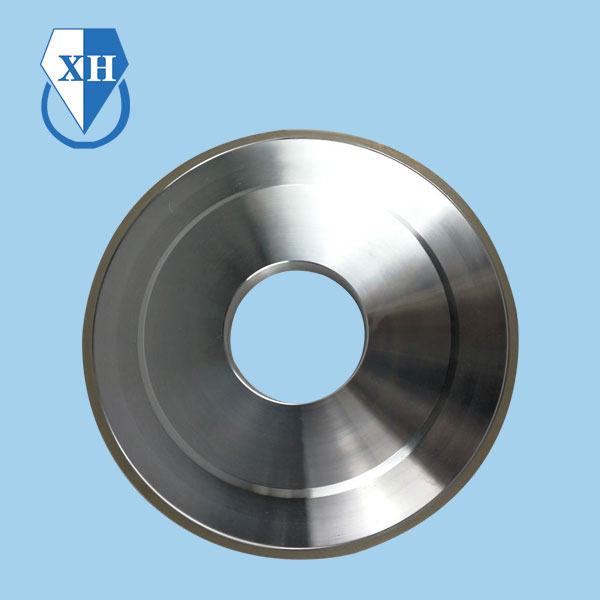

3. Molding: The mixture is then placed into a mold that is shaped according to the desired wheel structure. The mold can have the shape of a flat wheel, cylindrical wheel, cup wheel, or another form based on the intended application.

4. Compaction: Pressure is applied to the mixture within the mold. The pressure compacts the abrasive grains and the binder, helping to create a dense and solid structure. This compaction is essential for achieving uniform distribution of abrasive grains and for enhancing the mechanical stability of the wheel.

5. Sintering: The mold containing the compacted mixture is subjected to high temperatures in a sintering furnace. During sintering, the heat causes the bronze matrix or binder to melt and fuse with the abrasive grains. As the mixture cools, the bronze solidifies and forms a strong bond with the abrasive material. This process is critical for ensuring that the abrasive grains remain securely attached to the wheel.

6. Cooling and Shaping: After sintering, the grinding wheel is allowed to cool. It may then undergo additional shaping and sizing processes to achieve the desired dimensions, including diameter, thickness, and wheel structure.

7. Dressing and Profiling: The wheel may be dressed and profiled to ensure it has the required shape and sharpness before use. This can involve the removal of any excess material, reshaping, or truing to maintain the wheel's accuracy.

The resulting grinding wheel is a solid, well-bonded composite of abrasive material and bronze matrix. The sintering process not only creates a strong bond but also ensures that the abrasive grains are evenly distributed, enhancing the wheel's cutting efficiency and longevity. The choice of abrasive material and its bonding with the bronze matrix is fundamental in determining the grinding wheel's performance and suitability for specific applications.