Crafting the Foundations: Common Materials in Manufacturing Solar Panel Mounts for Metal Roofs

2024-02-02

Introduction:

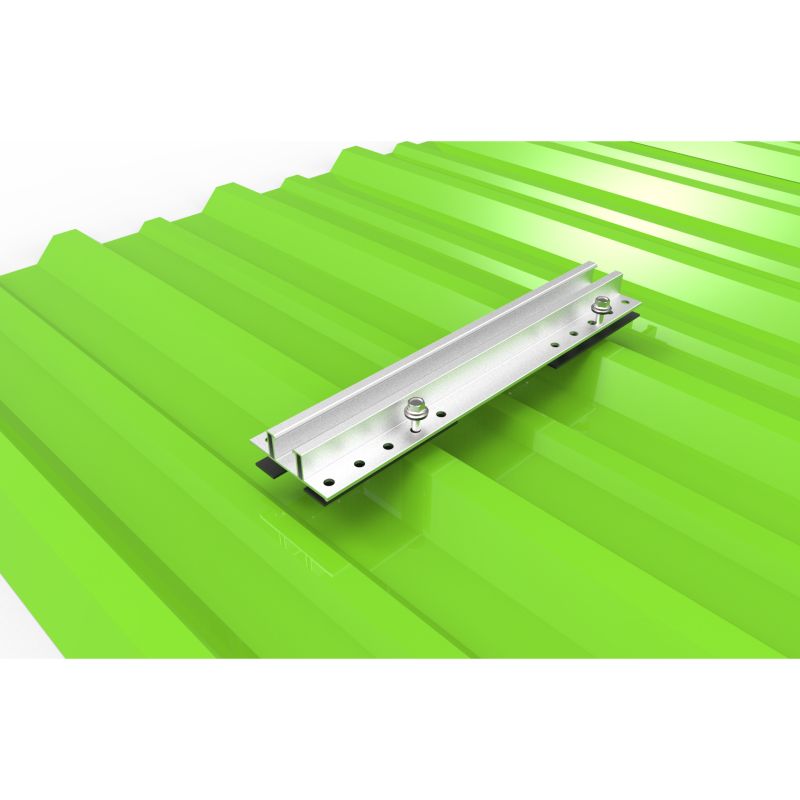

The widespread adoption of solar energy has spurred innovations not only in solar panel technology but also in the materials used to anchor these panels securely to various surfaces. Metal roofs, renowned for their durability and energy-efficient properties, require specialized mounting systems to ensure a seamless integration of solar panels. In this blog post, we delve into the common materials employed in the manufacturing of solar panel mounts specifically designed for metal roofs.

1. Aluminum:

Aluminum stands out as a popular choice for manufacturing solar panel mounts for metal roofs. Its lightweight yet robust nature makes it an ideal material, providing strength without adding unnecessary load to the roof structure. Additionally, aluminum boasts excellent corrosion resistance, crucial for withstanding exposure to the elements over the lifespan of the solar panel installation.

2. Stainless Steel:

Known for its exceptional strength and corrosion resistance, stainless steel is often utilized in the manufacturing of solar mounts for metal roofs. Stainless steel offers durability and resilience in challenging environmental conditions, making it well-suited for long-term outdoor use. Its resistance to corrosion ensures that the mounting hardware remains intact and secure, contributing to the overall stability of the solar panel system.

3. Galvanized Steel:

Galvanized steel is another common material employed in the manufacturing of solar panel mounts for metal roofs. This type of steel is coated with a layer of zinc to enhance its corrosion resistance. Galvanized steel mounts are robust and durable, making them suitable for withstanding the rigors of varying weather conditions. The zinc coating provides an additional protective layer against rust and corrosion.

4. Anodized Aluminum:

Anodized aluminum is a specialized form of aluminum that undergoes an electrochemical process to enhance its surface properties. This process results in a corrosion-resistant and abrasion-resistant layer on the aluminum. Anodized aluminum solar mounts offer an added level of protection against environmental factors, ensuring longevity and reliability in harsh outdoor settings.

5. High-Density Polyethylene (HDPE):

Some solar panel mounts incorporate components made from high-density polyethylene. HDPE is a durable and lightweight plastic that is resistant to moisture, chemicals, and UV radiation. It is often used for parts like bushings, insulators, or protective coatings in solar mounting systems, providing insulation and protection against potential abrasion.

6. UV-Resistant Polymers:

Components of solar mounts that are exposed to sunlight may be crafted from UV-resistant polymers. These polymers are designed to withstand prolonged sun exposure without degrading or losing their structural integrity. Incorporating UV-resistant materials ensures that the solar panel mounts remain reliable and visually appealing over time.

Conclusion:

The materials used in manufacturing solar panel mounts for metal roofs play a pivotal role in the longevity, reliability, and performance of solar installations. From aluminum and stainless steel to galvanized steel, anodized aluminum, and specialized polymers, each material brings its unique set of properties to the table. As solar technology continues to advance, the careful selection of these materials ensures that solar panel mounts for metal roofs are not only durable but also capable of seamlessly integrating with the robust characteristics of metal roofing systems. This harmonious combination lays the foundation for a sustainable and resilient solar energy future.