Choosing the Right Bracket: Key Design Considerations for Structural and Mechanical Applications

2024-06-20

Selecting the appropriate bracket part for structural or mechanical applications is crucial for ensuring stability, safety, and efficiency. Brackets come in various shapes, sizes, and materials, each suited for different purposes. To make an informed choice, several key design considerations must be taken into account. In this blog, we will explore these considerations to help you select the right bracket for your project.

1. Load Capacity

Understanding Load Requirements:

- Static Loads:

- Consider the maximum weight the bracket needs to support without any movement. For example, in shelving systems, the static load would be the weight of items placed on the shelf.

- Dynamic Loads:

- Take into account any dynamic loads, which involve movement or varying forces. This is especially important in mechanical applications where components might move or vibrate.

Material Strength:

- Steel and Aluminum:

- Steel brackets typically offer higher load capacities due to their strength, while aluminum brackets are lighter but may have lower load limits. Choose the material that matches the load requirements of your project.

- Stainless Steel:

- For applications requiring corrosion resistance and high strength, stainless steel brackets are ideal, especially in outdoor or marine environments.

2. Environmental Conditions

Corrosion Resistance:

- Outdoor Use:

- If the bracket will be exposed to the elements, select materials that resist corrosion, such as galvanized steel, aluminum, or stainless steel.

- Chemical Exposure:

- In industrial settings where chemicals are present, ensure the bracket material is resistant to those chemicals to prevent degradation.

Temperature Tolerance:

- Extreme Temperatures:

- Consider the operating temperature range. Some materials, like certain plastics or alloys, may degrade or lose strength at high temperatures. Conversely, very low temperatures can make some metals brittle.

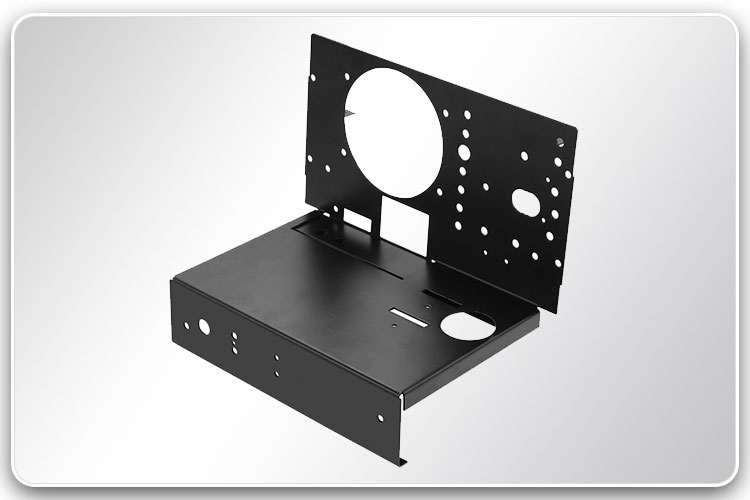

3. Bracket Design and Geometry

Shape and Configuration:

- Angle Brackets:

- Ideal for right-angle connections and providing support to perpendicular joints.

- U-Brackets and Z-Brackets:

- Useful for specific applications where the shape provides additional stability or fits particular design constraints.

Mounting and Installation:

- Pre-Drilled Holes:

- Brackets with pre-drilled holes simplify installation. Ensure the hole sizes and spacing match your mounting requirements.

- Adjustability:

- For applications requiring flexibility, consider adjustable brackets that allow for changes in position or angle after installation.

4. Aesthetic Considerations

Visible Applications:

- Decorative Finishes:

- In applications where the bracket will be visible, such as interior shelving or architectural details, choose brackets with a finish that complements the surrounding decor. Options include polished metals, painted finishes, and decorative designs.

Custom Designs:

- Architectural Features:

- For custom or high-end projects, consider brackets that can be fabricated to specific designs, adding both functional support and aesthetic value.

5. Compliance and Standards

Building Codes and Regulations:

- Safety Standards:

- Ensure the selected brackets meet local building codes and safety regulations. This is particularly important in structural applications to guarantee safety and compliance.

Industry Standards:

- Certification:

- Look for brackets that adhere to industry standards and certifications, which ensure quality and reliability.

6. Cost and Availability

Budget Constraints:

- Material Costs:

- Balance the need for strength and durability with budget constraints. While high-quality materials like stainless steel are more expensive, they may be necessary for certain applications.

- Bulk Purchasing:

- For large projects, consider bulk purchasing options which can reduce overall costs.

Lead Time and Supply Chain:

- Availability:

- Ensure the brackets you choose are readily available to avoid project delays. Custom or specialized brackets might have longer lead times.

Conclusion

Selecting the right bracket part for structural or mechanical applications involves careful consideration of various factors, including load capacity, environmental conditions, bracket design, aesthetics, compliance, and cost. By understanding these key design considerations, you can make informed decisions that ensure the stability, safety, and efficiency of your project. Whether you need robust support for heavy loads, corrosion-resistant materials for outdoor use, or aesthetically pleasing designs for visible applications, the right bracket choice is essential for successful implementation.