Top Solar Panel Mounting Rails Factories in China: Key Suppliers and Industry Leaders

2026-01-08

As the demand for renewable energy continues to soar, China has become a global powerhouse in solar technology, particularly in the manufacturing of mounting rails—a critical component for solar panel installations. This blog, presented by Topfence, explores the leading factories in China that are driving innovation and setting industry standards. Whether you're a solar installer, project developer, or simply passionate about clean energy, we'll guide you through the key suppliers and industry leaders shaping this dynamic market. Get ready to discover the players behind the scenes and how they can impact your next solar project!

Introduction to Leading Rail Manufacturers in China's Solar Sector

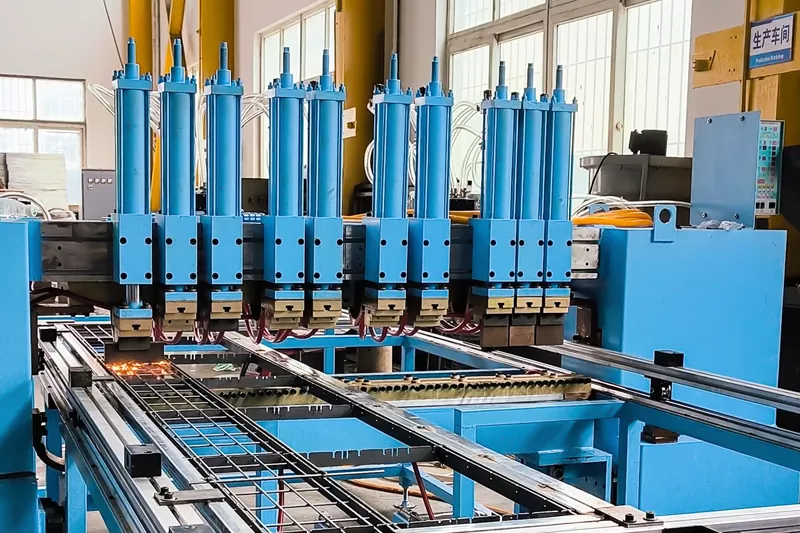

As China's solar sector undergoes rapid expansion, the role of rail manufacturers in supporting this growth has become increasingly pivotal. Leading companies in this niche are not just producing tracks; they're engineering specialized rail solutions that integrate seamlessly with solar farms, ensuring durability in harsh environmental conditions. These manufacturers focus on creating corrosion-resistant materials and modular designs that simplify installation across vast solar arrays, contributing to more efficient and cost-effective energy projects nationwide.

What sets these top rail manufacturers apart is their commitment to innovation beyond traditional railway applications. They collaborate closely with solar developers to tailor products like adjustable mounting systems and lightweight alloys, which enhance flexibility in panel positioning and reduce structural load. This synergy has led to breakthroughs in large-scale photovoltaic deployments, particularly in challenging terrains such as deserts or high-altitude regions, where reliable rail infrastructure is crucial for maximizing solar energy capture.

By prioritizing sustainability and precision engineering, these manufacturers help streamline the entire solar installation process, from initial site preparation to long-term maintenance. Their contributions underscore how industrial expertise in rail manufacturing is being repurposed to accelerate China's renewable energy ambitions, fostering a more interconnected and resilient solar infrastructure that supports global efforts toward carbon neutrality.

Innovative Designs Enhancing Solar Panel Stability and Efficiency

In recent years, the solar energy sector has witnessed a surge in innovative designs that significantly boost both the stability and efficiency of solar panels. One notable advancement is the development of bifacial panels, which capture sunlight from both sides, increasing energy yield by up to 30% compared to traditional models. These panels are often paired with tracking systems that adjust their angle throughout the day, optimizing exposure to the sun's rays. Additionally, materials like perovskite are being integrated into photovoltaic cells, enhancing light absorption and reducing energy loss, thereby improving overall panel performance in various weather conditions.

Beyond materials and tracking, structural innovations are playing a key role in enhancing stability. For instance, lightweight yet durable frames made from advanced composites or aluminum alloys are being used to withstand harsh environmental factors such as high winds, heavy snow, and corrosion. Some designs incorporate flexible or foldable panels that can be easily installed on uneven surfaces or mobile applications, reducing installation costs and increasing adaptability. These improvements not only extend the lifespan of solar installations but also ensure consistent energy production, making solar power more reliable and cost-effective for both residential and commercial users.

Looking ahead, emerging technologies like smart solar panels equipped with sensors and IoT connectivity are set to revolutionize the field. These panels can monitor their own performance in real-time, detect issues like shading or dirt accumulation, and automatically adjust settings to maintain peak efficiency. Combined with energy storage solutions and grid integration, these innovations are paving the way for a more resilient and efficient solar energy ecosystem. As research continues, we can expect even more groundbreaking designs that push the boundaries of what solar panels can achieve.

Key Factors in Selecting High-Quality Mounting Rails for Solar Projects

Choosing the right mounting rails for solar installations can have a significant impact on the longevity and performance of the entire system. These rails form the structural backbone, supporting solar panels through various weather conditions and environments. Factors such as material durability, corrosion resistance, and load-bearing capacity are critical; for instance, aluminum alloys are preferred for their lightweight yet sturdy properties, but not all alloys are created equal—some may degrade faster in coastal areas due to salt exposure. It's essential to evaluate the rail's design against project-specific needs, including wind and snow loads, to ensure stability over decades of use.

Beyond mere strength, installation flexibility and compatibility play a key role in determining rail quality. High-quality systems often feature modular designs that allow for easy adjustments and expansions, accommodating different panel sizes and roof types without extensive modifications. This adaptability can save time and costs during setup, while also facilitating future maintenance or upgrades. Additionally, consider how the rails integrate with mounting hardware and accessories; a seamless fit reduces potential weak points and enhances overall system reliability, preventing issues like panel misalignment or vibration-induced wear.

Cost-effectiveness shouldn't overshadow quality, as cutting corners on rails can lead to expensive repairs or reduced energy output down the line. Investing in certified products from reputable manufacturers, which undergo rigorous testing for factors like UV resistance and thermal expansion, can provide peace of mind and better return on investment. Always review warranty terms and supplier support, as these aspects indicate confidence in product durability and can aid in troubleshooting. By prioritizing these key factors, project managers can ensure their solar arrays remain efficient and secure, maximizing energy generation for years to come.

Sustainability Practices and Environmental Impact of Production

In today's manufacturing landscape, sustainability practices are no longer just a trend but a core component of operational strategy. Companies are increasingly adopting environmentally friendly methods to reduce their ecological footprint while maintaining efficiency. This shift involves implementing energy-efficient technologies, optimizing supply chains to minimize waste, and sourcing raw materials from renewable or recycled sources, ensuring that production processes align with long-term environmental stewardship.

A key aspect of these initiatives is the careful management of natural resources. For instance, many industries now focus on water conservation through closed-loop systems that recycle water for repeated use, drastically cutting down on consumption. Additionally, by investing in renewable energy sources like solar or wind power, producers can significantly lower greenhouse gas emissions, contributing to a cleaner atmosphere and mitigating climate change impacts in the long run.

Beyond resource management, the environmental impact of production extends to waste reduction and product lifecycle considerations. Forward-thinking companies are designing products for durability and recyclability, making it easier to reuse materials at the end of a product’s life. This circular approach not only minimizes landfill contributions but also fosters economic resilience by creating new markets for recycled goods, ultimately shaping a more sustainable industrial ecosystem.

Global Market Reach and Export Strategies of Top Suppliers

Top suppliers excel by building extensive global networks that span continents, allowing them to tap into diverse customer bases and reduce dependency on any single market. They often leverage local partnerships and digital platforms to streamline logistics, ensuring products reach clients efficiently while adapting to regional regulations and cultural preferences. This broad reach not only drives revenue growth but also fosters resilience against economic fluctuations, making them standout players in an increasingly interconnected world.

Effective export strategies for leading suppliers involve a mix of market research, tailored marketing efforts, and agile supply chain management. By analyzing trends and consumer behaviors in target regions, they can customize offerings to meet specific needs, such as eco-friendly products in Europe or tech innovations in Asia. Additionally, they invest in technology to enhance visibility and communication across borders, enabling real-time adjustments that keep them ahead of competitors and responsive to emerging opportunities.

To truly differentiate themselves, top suppliers go beyond standard practices by embracing innovation and sustainability in their export approaches. They might implement advanced data analytics to predict demand shifts or adopt green logistics to appeal to environmentally conscious markets. By fostering a culture of continuous improvement and ethical business practices, they not only expand their global footprint but also build lasting trust with international partners, setting a high bar for industry excellence.

Future Trends and Technological Advancements in Solar Mounting Systems

As solar energy adoption accelerates globally, mounting systems are evolving beyond simple racks to become smarter and more integrated. Innovations like active tracking systems that adjust panel angles throughout the day are boosting efficiency significantly, while lightweight materials such as aluminum composites and advanced polymers reduce installation costs and environmental impact. These advancements not only enhance energy capture but also make solar installations more feasible in diverse environments, from urban rooftops to rugged terrains.

Another key trend is the rise of modular and prefabricated mounting solutions, which streamline installation processes and cut down on labor time. Companies are developing systems that snap together easily or adapt to various roof types without complex modifications. This flexibility allows for quicker deployments and scalability, supporting both residential projects and large-scale solar farms with minimal disruption. Additionally, these designs often incorporate weather-resistant features, ensuring durability in harsh climates without compromising performance.

Looking ahead, smart technologies are set to redefine solar mounting, with embedded sensors and IoT connectivity enabling real-time monitoring and predictive maintenance. Imagine systems that detect wind stress or soil shifts, automatically adjusting to prevent damage and optimize energy output. Such innovations promise to lower long-term operational costs and enhance reliability, making solar power more accessible and efficient for communities worldwide. This shift toward intelligent, adaptive systems underscores the industry's focus on sustainability and resilience in an ever-changing energy landscape.

FAQ

Among the top factories, companies like Renusol, Unirac, and Schletter are often highlighted for their quality and scale, with local firms such as Suzhou East Solar gaining reputation for competitive pricing.

Chinese factories excel due to cost efficiency, advanced automation in production, and strong supply chain integration, allowing them to serve global markets with reliable and affordable solutions.

They typically use high-grade aluminum or steel, apply corrosion-resistant coatings, and conduct rigorous testing under various environmental conditions to meet international standards like IEC and UL.

Recent trends include lightweight designs for easier installation, adjustable components for varied roof types, and integration of smart tracking systems to enhance energy capture efficiency.

Emerging companies such as Clenergy and Mounting Systems focus on eco-friendly materials and modular designs, offering customizable options for residential and commercial projects.

They deal with fluctuating raw material costs, increasing environmental regulations, and the need for continuous innovation to differentiate from low-cost competitors while maintaining quality.

Conclusion

China stands as a global hub for solar panel mounting rails, with top factories leading the industry through innovation and expertise. These key suppliers, including prominent manufacturers like those highlighted in the sector, have established robust production capabilities that cater to both domestic and international markets. Their introduction into the solar realm involves not just manufacturing but also pioneering designs that enhance panel stability and efficiency, such as advanced aluminum alloys and modular systems. When selecting high-quality rails for projects, factors like durability, corrosion resistance, and ease of installation are paramount, driving these leaders to prioritize precision engineering. Moreover, sustainability practices are integral, with many factories adopting eco-friendly production methods to minimize environmental impact, aligning with global green energy trends.

Looking ahead, these industry leaders are expanding their global market reach through strategic export strategies, leveraging China's competitive manufacturing advantages. Future trends point toward technological advancements, including smart mounting systems with integrated monitoring and lightweight materials for increased versatility. This evolution not only boosts efficiency but also supports the broader adoption of solar energy worldwide. By combining innovative designs, sustainable operations, and forward-thinking approaches, China's top mounting rail factories are poised to shape the future of solar infrastructure, ensuring reliable and efficient solutions for diverse applications.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/